What's the difference?

Modelling UK energy to explore the future grid:

The Generation Game

We used detailed records of all the UK’s electricity sources since 2015 to create a timeline of exactly how much output the UK’s wind farms produced, every 30 minutes, in all weather conditions, over the last 10 years. What if we doubled it? Or TREBLED it? This model uses real-world data to see what happens as renewables scale up.

Storage

When the wind drops on a cold dark winter’s night, and the output from wind turbines falls to a trickle, the future grid will rely upon energy stockpiles stored in batteries or other energy reservoirs. This model allows you to explore whether different forms of storage will be able to store enough energy and at what cost. See here why batteries alone are not a cost-effective solution.

Meeting future electricity demand

Electric cars and electric heat pumps are set to add yet more demand on the UK's electricity grid. How much will they add, what other consequences might they have? How could non-energy factors, such as home insulation, affect demand?

The aim of the game is to keep the lights on at minimum cost

Scroll down for controls

Turbine manufacturers are now adapting their power station turbines to run on hydrogen instead of natural gas.

Photo: Wikimedia/ Siemens.com

The Numbers Behind The Model

The scrollable table below reveals the calculations behind the graphs, and how the model works

It is a useful tool for checking the details of what the model is actually doing.

(Click for notes explaining how the model works)

to hide explanatory notes)

National Grid data provides hourly figures for electricity supply (and by implication, demand). We use these figures to apply real-world performance to hypothetical scenarios. For example, the figures show, hour-by-hour, exactly how much wind power was produced in 2019. Based on these records, our model speculates that if there had been double the number of wind turbines installed in 2019, then the weather-dependant hourly power would have been double what was recorded.

The model uses the new values to see if the new projected values for power generated would have met demand at that moment. If there is excess power, it can be used to charge storage (batteries, pumped hydro, hydrogen...), but is there is not enough to meet demand, then storage must make up the supply. There is also an adjustment for efficiency of the storage medium. For example, lithium-ion batteries are 80-95% efficient, meaning that for every 100kWh of electricity stored, the battery can return 80-95kWh to the grid.

Worked example

At 1am on 1st March, 2015, National Grid supplied 31.4GW of power to the grid to match demand (which must also have been 31.4GW):

| Period | Wind | CCGT | Nuclear | Coal | Import/Export | Other | Total Supply (GW) |

| 22 Feb 2015, 01:00 | 1.6 | 4.8 | 7.8 | 13.4 | 2.5 | 1.4 | 31.4 |

The table shows there was 1.6GW of wind power, which we calculate to be 24% of

peak wind capacity

Peak Wind Capacity

We use the highest recorded wind-power up to that date as a rough proxy for the total available installed nameplate capacity, and use that to calculate a percentage value for wind power at that moment - how much power wind is producing as a percentage of installed capacity. Then we can use this hourly percentage to work out how much power might have been produced if there were double or treble the amount of turbines installed, etc.

The average percentage wind turbine output over time for the period 2015-2021 works out around 41%, which is pretty close to the 45% load factor achieved by large modern offshore turbines that we assume will form the bulk of future wind power. Older onshore turbines have a much lower load factor - around 25% - due to less windy onshore locations and also because they can't reach the more consistent winds 100m above the ground.

Why does the model use 14GW of wind as its starting point? - We know that there was 24GW of wind power installed at the end of 2021, but the peak wind power recorded was only 14GW. For this reason, our model uses a starting point of 14 GW of wind power already installed instead of 24GW. This is a fairly good approximation to 24GW of lower-efficiency turbines (24GW x 25% = 14GW x 43%)

at the time. Now we ask What If ... there had been a different amount of wind power installed at that moment? We already know that wind turbines were working at 25% of capacity at that moment, so we could have expected 100GW of installed capacity to yield 25GW (100GW x 25%).

We also know that demand at that moment was 31.4GW (because demand = supply), so we need an extra 6.4GW of electricity from storage in order to meet demand. We use the most efficient storage first - batteries. Supplying 6.4GW of power for 1 hour requires 6.4GWh of electric charge (energy) from the batteries. Lithium-ion batteries are 85% efficient, so during discharge, only 85% of the original energy comes out, so we actually need to discharge 7.5GWh (6.4 / 85%) to supply 6.4GWh back to the National Grid. Once the batteries are exhausted, then we turn to the next most efficient storage, Pumped Storage Hydro (80% efficient), and then Hydrogen+CCGT (48% efficient).

When there is more supply than demand, there is a surplus of electricity, so now energy can be spared to recharge the batteries and other storage, in order of efficiency.

Full charge/discharge cycles completed:

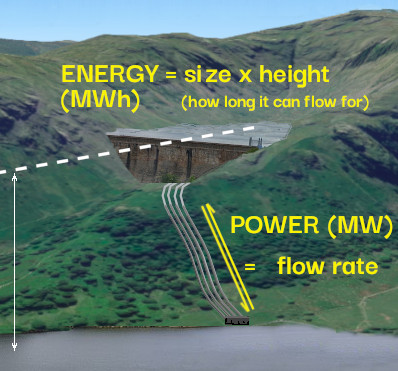

Watts measure POWER, such as the brightness of a 100W light bulb.

Watts measure POWER, such as the brightness of a 100W light bulb.